Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

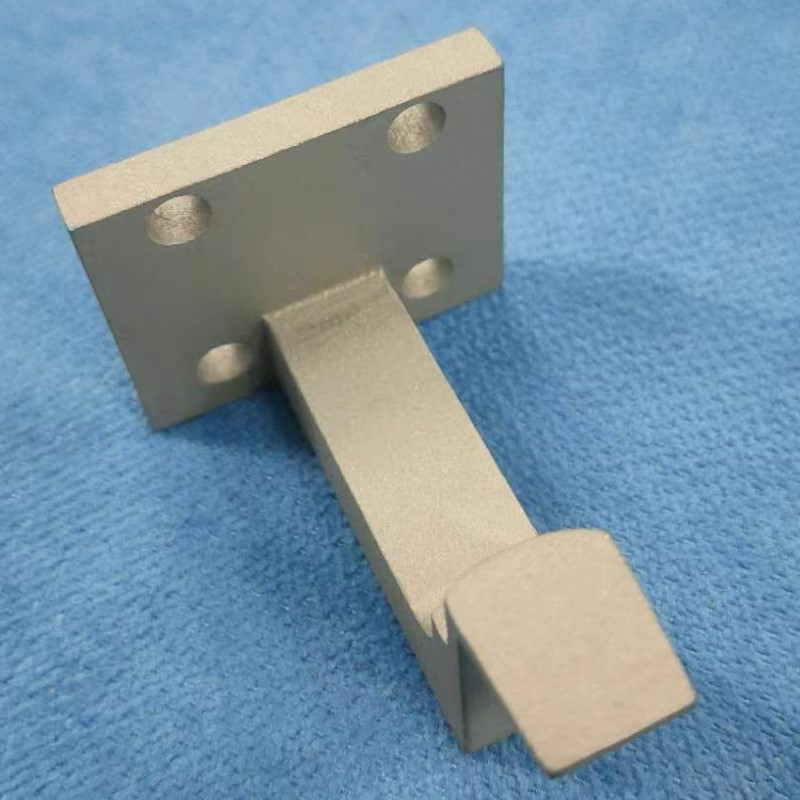

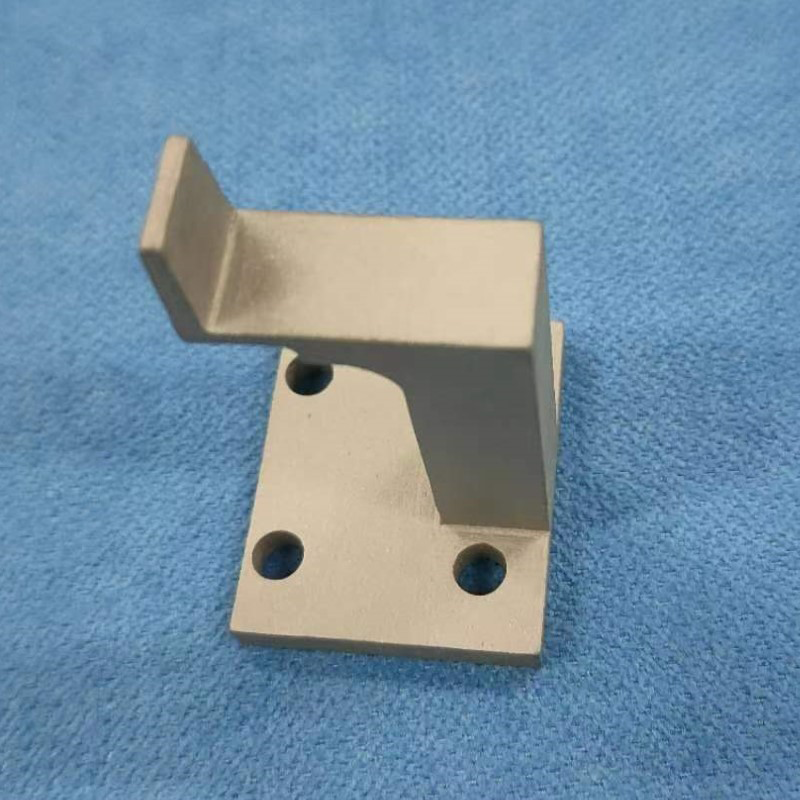

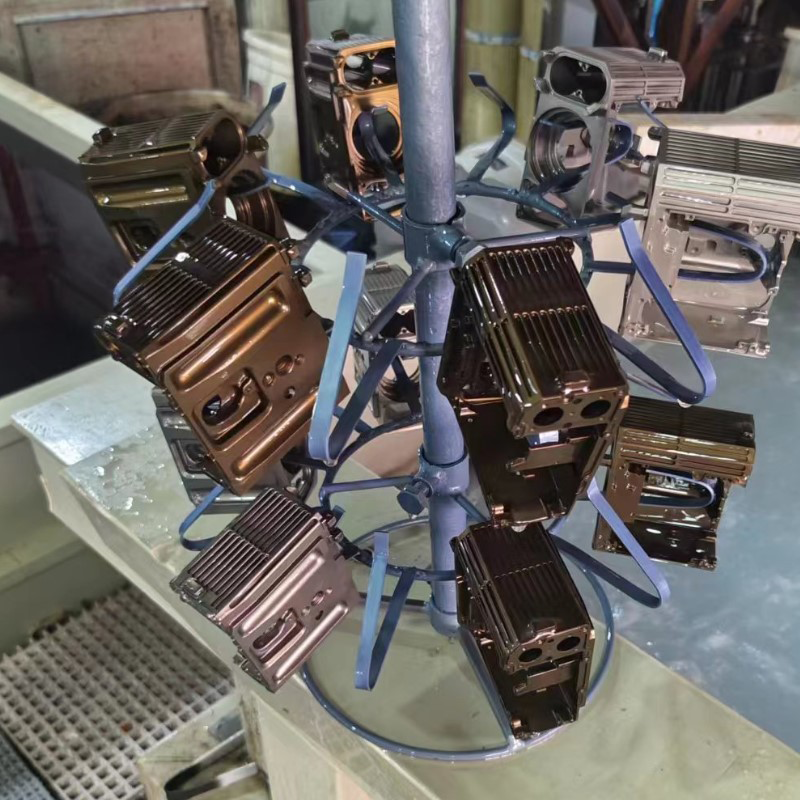

Surface Finishing Service

Elevate the aesthetics and functionality of your components with our high-quality surface finishing services, enhancing the appeal and performance of parts produced through various manufacturing processes. We specialize in delivering top-notch metal, composites, and plastic finishing services, helping transform your envisioned prototypes or parts into reality

Our Portfolio of Surface Finishing

Benefit from our exceptional part finishing services, where our expert teams specialize in plastic, composite, and metal surface finishing. Our state-of-the-art machines and advanced infrastructure ensure the realization of your ideas with precision and excellence.

Our Surface Finishing Specifications

Part surfacing finishing techniques can either be for functional or aesthetic purposes. Each technique has requirements, such as materials, color, texture, and price. Below are the specifications of the plastic finishing techniques rendered by us.

|

Name

|

Decsription

|

Materials

|

Color

|

Texture

|

|

|

Anodizing

|

Anodizing improves corrosion

resistance, enhancing wear

resistance and hardness, and

protecting the metal surface.

Widely used in mechanical parts,

aircraft, and automobile parts,

precision instruments, etc.

|

Al uminum |

Clear, black, grey,

red, blue, gold.

|

Smooth,

matte finish.

|

|

Bead Blasting

|

Bead blasting results in parts

with a smooth surface with a matte

texture. Used mainly for visual

applications and can be followed

by other surface treatments.

|

ABS, Aluminum,

Brass, Stainless

Steel, Steel

|

N/A |

Matte

|

|

Powder Coating

|

Powder coating is a type of

coating that is applied as a free- f lowing, dry powder. Unli ke conventional liquid paint which is delivered via an evaporat ing solvent, powder coating is |t ypically applied e lectrostatically and then cured under heat or with ultraviolet 1 ight. |

Aluminum,

Stainless Steel,

Steel

|

Black, any RAL code

or Pantone number

|

Gloss or

semi-gloss

|

|

Electroplating

|

Electroplating can be functional,

decorative or corrosion-related.

Many industries use the process,

including the automotive sector,

in which chrome-plating of steel

automobile parts is common.

|

Aluminum, steel,

stainless steel

|

N/A |

Smooth, glossy

finish

|

|

Polishing

|

Polishing is the process of

creating a smooth and shiny

surface, either through physical

rubbing of the part or by chemical

interference. The process produces

a surface with significant

specular reflection, but in some

materials can reduce diffuse

reflection.

|

Aluminum, Brass,

Stainless Steel,

Steel

|

N/A |

Glossy

|

|

Brushing

|

Brushing is a surface treatment

process in which abrasive belts

are used to draw traces on the

surface of a material, usually for

aesthetic purposes.

|

ABS, Aluminum,

Brass, Stainless

Steel, Steel

|

N/A |

Satin

|

|

Painting

|

Painting involves spraying a layer of paint onto the surface of the part. Colors can be matched to a Pantone color number of the customer’s choosing, while finishes range from matte to gloss to metallic.

|

Aluminum, Stainless Steel, Steel

|

Custom |

Gloss,

semi-gloss, flat, metallic, textured |

|

Alodine

|

Chromate conversion coating, more commonly known by its brand name Alodine, is a chemical coating that passivates and protects aluminum from corrosion. It is also used as a base layer before priming and painting parts.

|

Aluminum

|

Clear, Gold |

Same as before

|

|

Part Marking

|

Part marking is a cost-effective way to add logos or custom lettering to your designs and is often used for custom part tagging during full-scale production.

|

All materials

|

Custom |

N/A

|

The Feature of Product

- Versatile Material Expertise:Surface Finishing Service caters to a variety of materials, including plastics, composites, and metals.

- Customized Finishing Options:Offers a range of finishing techniques tailored to meet specific aesthetic and functional requirements.

- State-of-the-Art Technology:Utilizes cutting-edge machinery and technology for precision and high-quality surface treatments.

- Expert Team in Material Surfaces:Boasts a team of experts with specialized knowledge in plastic, composite, and metal surface finishing.

- Comprehensive Finishing Solutions:Provides end-to-end finishing services, from preparation to the final surface treatment.

The Advantage of Product

- Enhanced Aesthetics:

Elevates the visual appeal of products by employing advanced surface finishing techniques. This includes achieving a polished and professional finish that enhances the overall aesthetics of the components, making them visually striking and appealing to end-users.

- Improved Durability:

The Surface Finishing Service goes beyond aesthetics to enhance the durability and longevity of products. By applying protective coatings and treatments during the finishing process, products gain resistance to wear, corrosion, and environmental factors.

- Optimized Functionality:

Surface finishing plays a crucial role in improving the functional aspects of components. By employing precision techniques and coatings, the service enhances the performance of parts, ensuring they not only meet but exceed industry standards. Whether it's reducing friction, enhancing conductivity, or optimizing surface hardness, the finishing process contributes to the superior functionality of the end product.

- Tailored Solutions:

Recognizing the diversity of design preferences and industry requirements, the Surface Finishing Service offers tailored solutions. This customization allows for the adaptation of finishing techniques to match specific design aesthetics, ensuring that the final product aligns seamlessly with the intended visual and functional goals. This flexibility caters to the unique needs of various industries and individual design specifications.

- Quality Assurance:

Quality is paramount in surface finishing, and the service places a strong emphasis on quality assurance. Rigorous quality control measures are implemented throughout the finishing process to ensure consistent and high-quality results. This commitment to quality guarantees that each finished product adheres to the highest standards, meeting or exceeding customer expectations.